Evaporators

Description

Evaporators are crucial instruments in laboratories and industries for removing solvents from liquid samples through evaporation. By applying controlled heat, evaporators accelerate the solvent removal process, leaving behind concentrated solutes or valuable components. These devices are indispensable in research, chemical synthesis, pharmaceutical production, and food science, offering precision and efficiency in various applications.

Types of Evaporators:

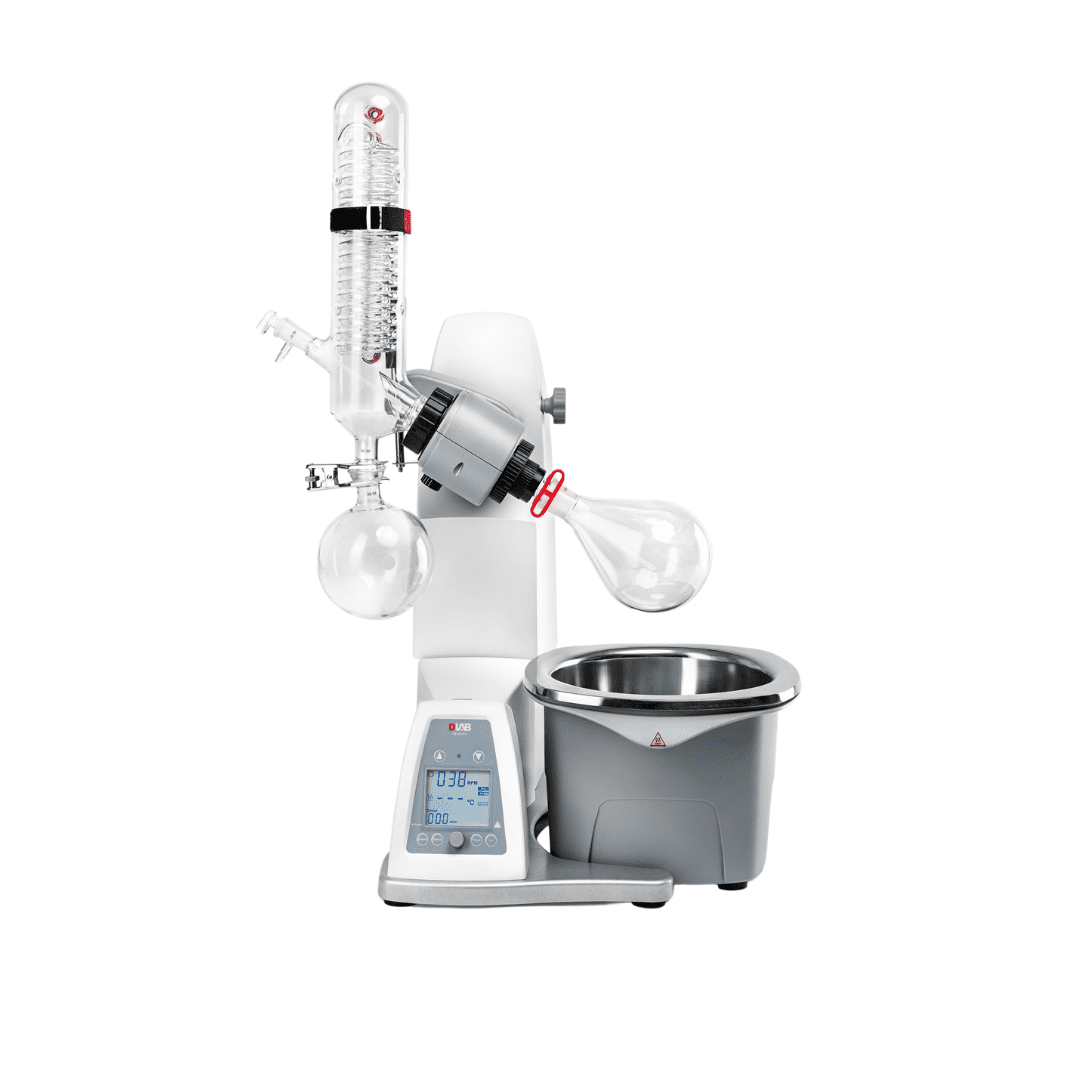

- Rotary Evaporators (Rotovaps): Ideal for gentle solvent removal, rotary evaporators use a rotating flask to create a thin film of liquid for rapid evaporation. Perfect for delicate samples in the pharmaceutical and chemical industries.

- Falling Film Evaporators: With vertical tubes that allow liquid to form a thin film, falling film evaporators are suitable for high heat transfer rates and are frequently used in industries such as food processing and chemical production.

- Thin Film Evaporators: These evaporators use a thin film to maximize surface area for heat transfer, making them ideal for solvent recovery and chemical concentration.

- Vacuum Evaporators: Operating under reduced pressure, vacuum evaporators lower the boiling point of solvents, preventing thermal degradation of heat-sensitive materials in applications like chemical concentration and pharmaceutical production.

Key Features:

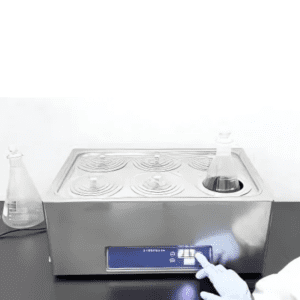

- Temperature Control: Precise temperature regulation for efficient solvent removal without compromising the sample’s integrity.

- Vacuum Systems: Lowering the boiling point of solvents, vacuum evaporators are ideal for sensitive compounds that require gentle evaporation.

- Capacity Options: Available in various sizes, from benchtop models for laboratory use to large-scale systems for industrial applications.

- Material Compatibility: Designed for use with various solvents, ensuring long-lasting performance in aggressive environments.

Applications:

- Pharmaceutical Industry: Solvent removal, concentration of active ingredients, and purification processes.

- Chemical Processing: Concentrating chemicals and recovering solvents for reuse in chemical synthesis.

- Food and Beverage Industry: Concentrating extracts, flavors, and juices, maintaining quality while enhancing processing efficiency.

- Environmental Testing: Solvent evaporation from samples for environmental analysis and testing.

Benefits: - High Efficiency: Evaporators help speed up the solvent removal process while ensuring precise control over temperature and pressure.

- Energy Saving: Many models are designed to optimize energy consumption while maintaining high throughput.

- Sample Integrity: With advanced features like vacuum systems, evaporators protect sensitive samples from thermal degradation.

Maintenance and Safety:

- Calibration: Regular calibration of temperature and pressure controls ensures consistent performance and accurate results.

- Cleaning and Care: Periodic cleaning of evaporator components is essential to prevent contamination and maintain efficiency.

- Safety Protocols: Always operate evaporators according to the manufacturer’s guidelines, particularly when handling volatile solvents.

Whether you’re in a laboratory or industrial setting, choosing the right evaporator ensures efficient and reliable solvent removal, making it an indispensable tool in various scientific and commercial processes.