Rotary Evaporators

Description

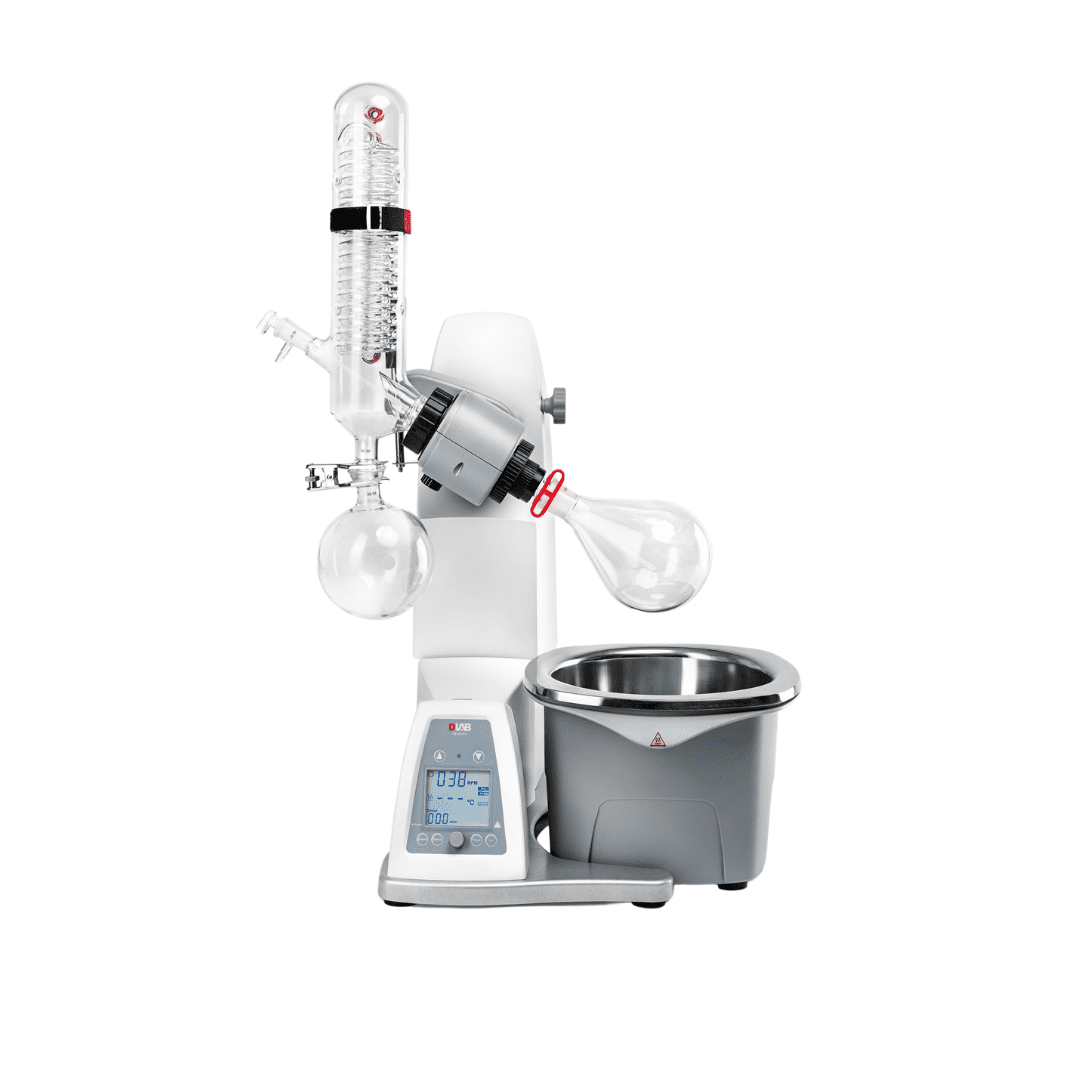

Rotary evaporators, often referred to as rotovaps, are specialized devices in laboratories designed to efficiently and gently remove solvents from samples by evaporation. They are indispensable in chemical, pharmaceutical, and research laboratories for applications such as solvent concentration, distillation, and purification processes.

Key Features:

- Rotary Flask: A rotating round-bottomed flask holds the sample, increasing the surface area for efficient evaporation.

- Heating Bath: The flask is partially immersed in a heated water or oil bath, providing controlled heating to facilitate solvent evaporation.

- Vacuum System: A vacuum pump creates reduced pressure, lowering the boiling point of solvents and enabling gentle evaporation at lower temperatures.

- Condenser: Vaporized solvents are condensed back into liquid form using a condenser, allowing for solvent recovery and minimizing loss.

Applications:

- Solvent Removal: Efficiently remove solvents from reaction mixtures, leaving behind desired products.

- Distillation: Separate solvents from non-volatile components based on differences in boiling points.

- Purification: Purify compounds by selectively evaporating solvents under controlled conditions.

- Molecular Cooking: In culinary applications, rotary evaporators are used to prepare distillates and extracts, enhancing flavors and aromas.

Benefits:

- Efficient Solvent Recovery: Recover solvents for reuse, reducing waste and operational costs.

- Gentle Evaporation: Minimize thermal degradation of sensitive compounds by evaporating solvents at lower temperatures.

- Increased Throughput: Handle multiple samples simultaneously, enhancing productivity in laboratory processes.

- Enhanced Safety: Operate under reduced pressure to lower the risk of solvent flammability and improve safety during evaporation.

Considerations:

- Sample Characteristics: Select appropriate rotary evaporator models based on the volume and nature of the samples to be processed.

- Solvent Properties: Consider the boiling points and volatilities of solvents to optimize evaporation conditions and equipment selection.

- Equipment Maintenance: Regularly maintain and calibrate the rotary evaporator to ensure consistent performance and extend its lifespan.

Incorporating rotary evaporators into laboratory workflows enhances efficiency, safety, and the quality of solvent removal and distillation processes. Their versatility and precision make them invaluable tools in various scientific and industrial applications.