Autoclaves

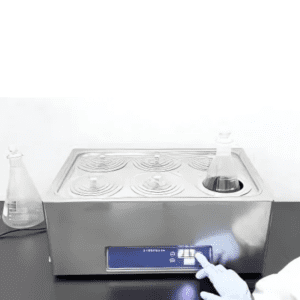

Description

An autoclave is a machine that uses steam under pressure to sterilize equipment and supplies, effectively killing microorganisms and ensuring aseptic conditions in medical, laboratory, and industrial settings. Invented by Charles Chamberland in 1879, autoclaves have become essential for processes requiring elevated temperature and pressure.

Types of Autoclaves:

- Gravity Displacement Autoclaves: These are the most common type, where steam enters the chamber, displacing air and creating a pressurized environment suitable for sterilization.

- Vacuum Autoclaves: Utilizing vacuum pumps, these autoclaves remove air from the chamber before introducing steam, ensuring thorough sterilization, especially for porous materials.

- Steam-Flush Pressure-Pulse Autoclaves: Combining steam flushing and pressure pulses, these autoclaves enhance air removal, ensuring effective sterilization of complex loads.

Key Features to Consider:

- Capacity: Autoclaves vary in size, from small benchtop models suitable for limited spaces to large floor-standing units capable of handling extensive loads.

- Cycle Control: Modern autoclaves offer programmable cycles with precise temperature and pressure settings, accommodating diverse sterilization requirements.

- Safety Mechanisms: Features such as pressure relief valves, door locks during operation, and automatic shut-off enhance user safety and prevent accidents.

Applications:

- Medical and Dental: Sterilizing surgical instruments, dental tools, and other medical devices to prevent infections.

- Laboratories: Sterilizing glassware, media, and waste materials to maintain aseptic conditions and prevent cross-contamination.

- Industrial: Curing rubber, processing composites, and other manufacturing processes requiring controlled heat and pressure.

Maintenance and Safety:

- Regular Inspection: Routine checks for leaks, pressure inconsistencies, and door seals ensure optimal performance and safety.

- Calibration: Periodic calibration of temperature and pressure gauges maintains accurate readings and effective sterilization cycles.

- Cleaning: Regular cleaning of the chamber and components prevents contamination and extends the autoclave’s lifespan.

- User Training: Proper training in operating procedures and emergency protocols ensures safe and effective use of the autoclave.

By selecting an autoclave that aligns with specific needs and adhering to maintenance protocols, institutions can ensure effective sterilization, contributing to the safety and success of their operations.